GAUSS

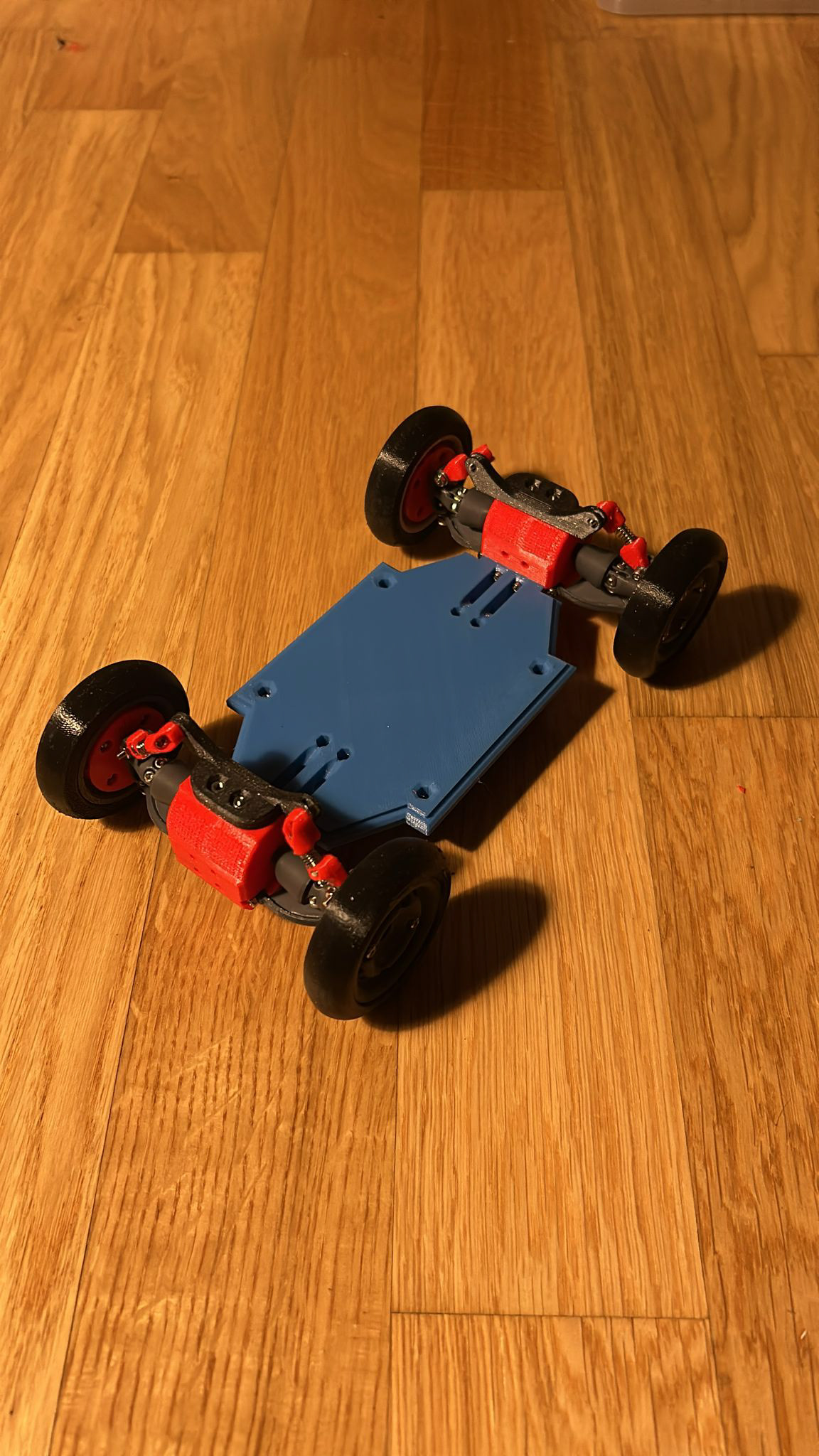

This project started as a detailed 3D model of the Gauss platform vehicle – a small, electric utility quad designed for flexibility and modularity. The miniature version was built at 1 to 8 scale and captures the core design principles of the full-size vehicle: lightweight, tough, and built to adapt.

The model features a swappable rear module, just like its real-life counterpart, and was designed to support various use cases – from logistics to rescue operations. Doors and compartments open, and even the suspension system is articulated to reflect the real mechanical layout.

Built with the usual mix of ingenuity and budget-awareness, the prototype combines 3D-printed parts, M3 screws and nuts, and brass tubing between 1 and 6 millimeters. The electronics and remote control? Sourced from a humble but heavily discounted RC car – because sometimes the smartest solution is already sitting on the toy shelf.

To speed things up and test consistency, I set up a small-scale production line. Several vehicle chassis were built in parallel, focusing on the battery pack, dual motor setup and suspension system. These core components were almost produced in a mini series, allowing me to refine tolerances, streamline assembly and test modular upgrades more efficiently.

One important lesson from the build: when working with M3 and especially M2 screws, threadlocker like Loctite is absolutely essential. Without it, even the best-engineered parts will slowly shake themselves loose. Tiny screws, big headaches.

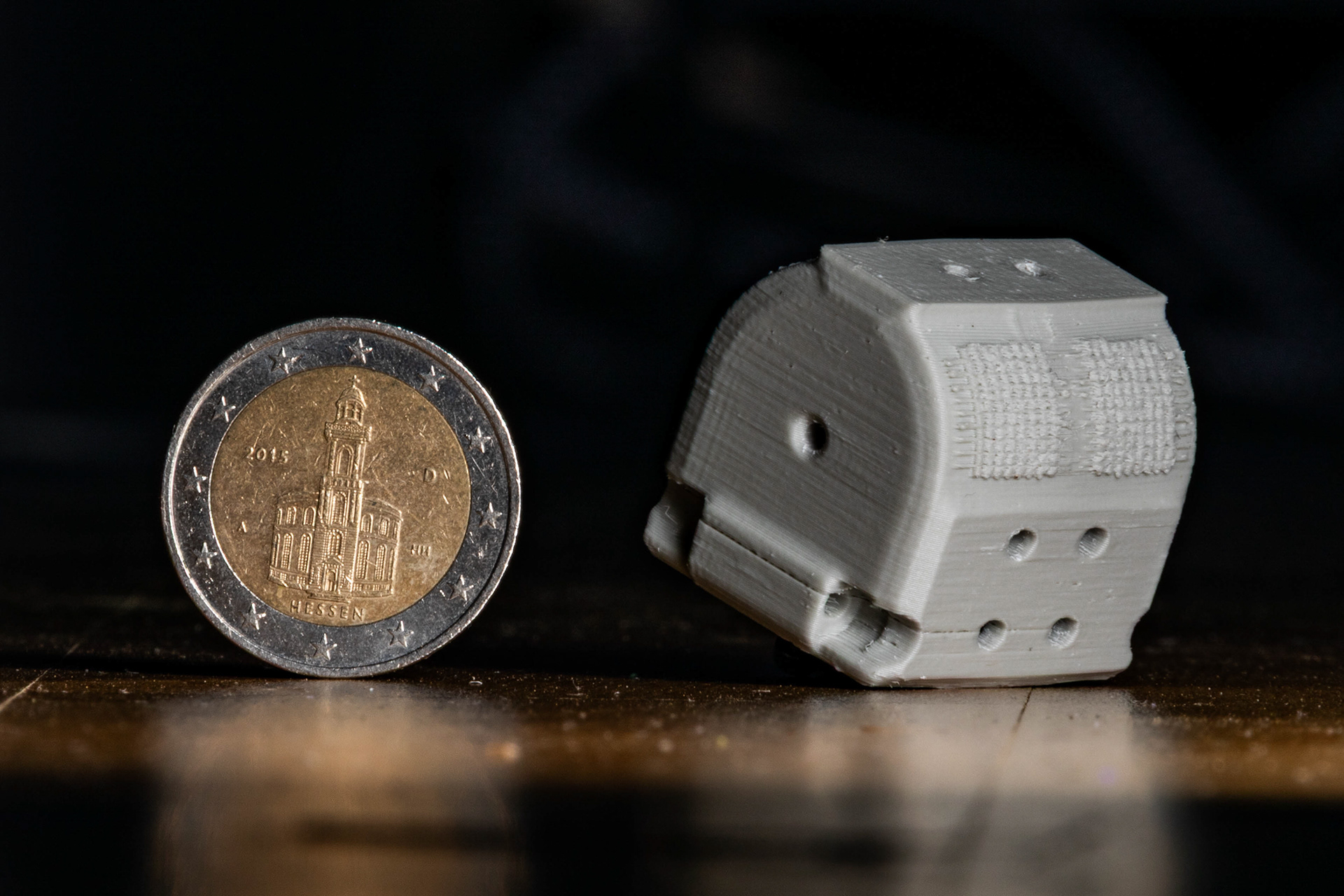

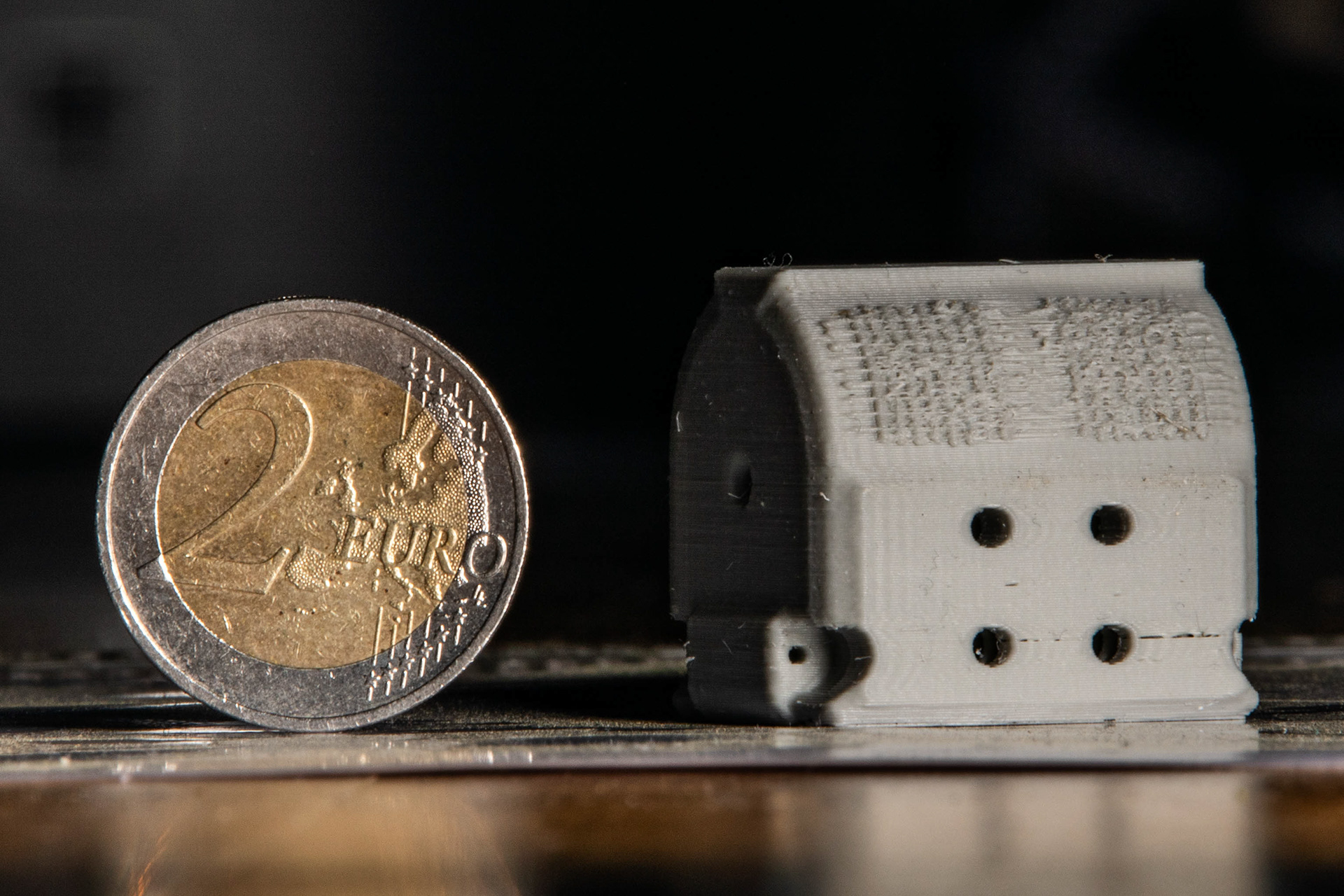

Shown up top is the dual motor module with a visible production issue. Cheap filament from a budget supplier caused delamination and cracking across entire batches – a reminder that cutting corners on material can cost more in the long run.